TAQA offers both mud-lubricated and oil sealed drilling motors that can be paired with almost any power section available on the modern market. Their premium design harnesses the expertise of decades of downhole drilling motor experience.

- About TAQA

- What we do

- Overview

- Well Solutions

- Overview

- Coiled Tubing, Intervention & Stimulation

- Completions

- Drilling Solutions

- Cementing

- Well Testing

- Early Production Facilities (EPF)

- Wireline

- Frac

- Slickline

- Inspection

- H2S & Safety

- Plug & Abandonment

- TAQA Ventures

- Products & Technologies

- Resources

- Sustainability

- Home

- Drilling Solutions

- Directional Drilling

- Mud Motors

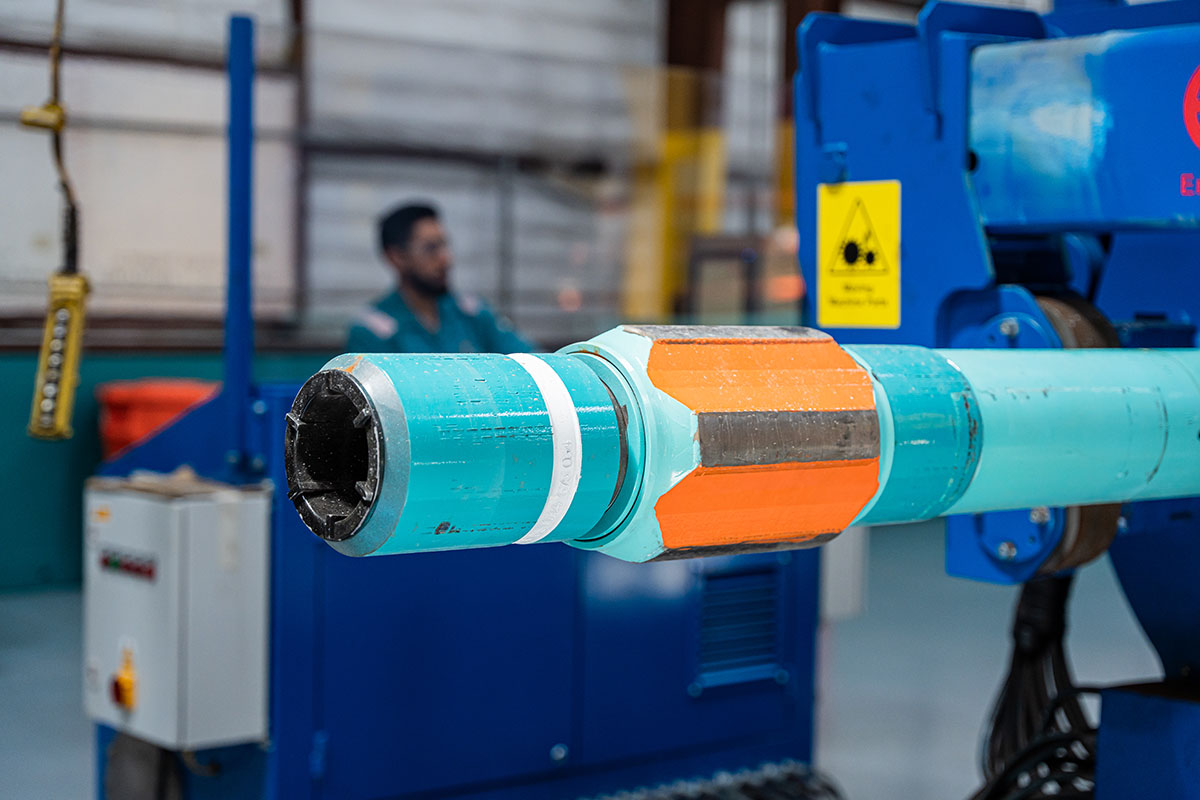

Mud Motors

Oil sealed bearing drilling motors

Oil sealed bearing drilling motors utilize a special rotary shaft seal designed specifically for drilling motor use that isolates the drilling fluid from the oil-lubricated bearing continually. The bearing assembly is designed to ensure reliable load transfers from the BHA to the bit.

Mud lubricated drilling motors

Mud lubricated drilling motors utilize custom radial and thrust bearings that enable operators to drill further, even in the harshest of conditions. The bearings are cooled and lubricated by the drilling fluid and are designed to ensure reliable load transfer from the BHA to the bit.

Challenge

In challenging conditions, it can be difficult to reach total depth in a single run. Higher temperatures, deviation, and poor hole conditions can hinder drilling performance. A motor with power and reliability is required to remain in the ground and meet specific drilling objectives.

Application

With a combination of radial and thrust bearings, the TAQA drilling motors can handle the toughest conditions, from high bit bounce and vibration applications in hard rock to high speed and temperature applications in softer formations. TAQA has extensive experience providing drilling motors for applications around the world – from extended-reach, horizontal applications in the Middle East and North America to geothermal drilling applications in Turkey and South America.

Results

TAQA partners with industry-leading power sections manufacturers to meet all run-per-minute and flow requirements within any condition. We also offer the highest kalsi rotational seals for maximum efficiency in any application. High-grade, heat-treated materials are used to construct each drilling motor, which we use precision machines to manufacture in Canada before shipping globally.

Main Features:

- Sealed and mud lubricated bearings available

- Large od transmission design

- Sizes from 3 1/8″ to 11 1/4″

- Maximum downhole hours

Contact us for enquries

Let's talk - What we do